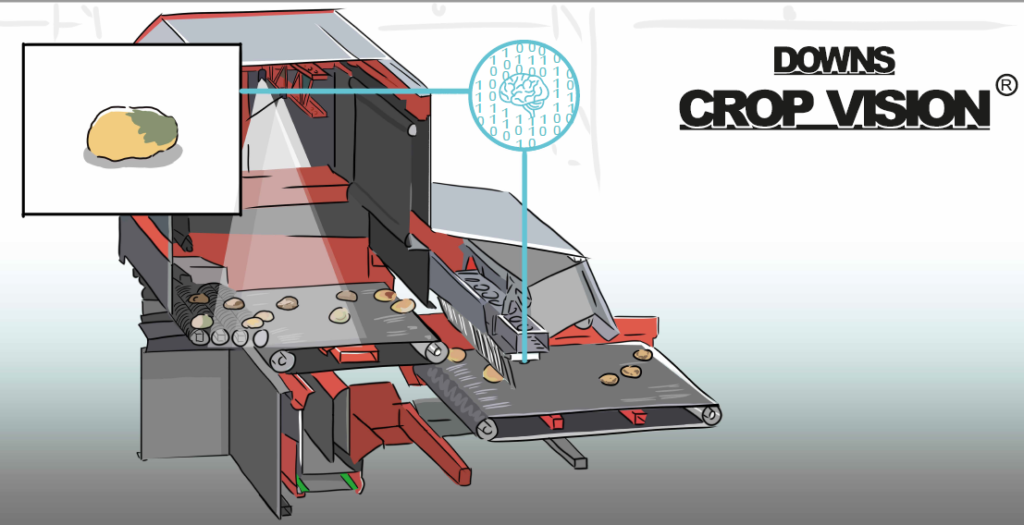

The DOWNS CropVision is a new-generation optical sorter for unwashed potatoes. Featuring the latest technological innovations, it enables quality sorting of potatoes before storage at high throughputs (up to 100 tons/h).

The DOWNS CropVision® is equipped with industrial cameras coupled with an Artificial Intelligence algorithm. This unique and patented combination enables the entire surface of the potato to be analyzed (360°), so that it can be accurately classified according to quality:

- Mound of earth

- Pebbles

- Miscellaneous waste

- Flawless potato

- Green potato

- Cut potatoes

- Spoiled potato

- Deformed potato

- Cracked potato

The DOWNS CropVision® has 3 outlets for potatoes: one for the product to be preserved, one for the product to be disposed of, and one for the second category. Depending on the operator’s choice, the ejector fingers will direct the product to the right outlet.

Thanks to its 360° analysis of each individual potato, DOWNS CropVision® provides the user with precise information on the potatoes stored. A wide range of information can be obtained, such as potato sizes per lot, or potato quality.

The DOWNS CropVision® is easy to use thanks to a touch screen, and can be integrated into DOWNS receiving hoppers and graders, up to a working width of 2,800mm. Like all DOWNS solutions, this optical potato sorter has been designed to limit the impact on the potatoes, thanks to a limited drop height between the 2 conveyors.

This new-generation optical sorter provides the solution to recurring pre-storage issues: manpower availability, sorting quality, economic profitability, health safety and environmental impact.

Get more information by downloading the attached brochure!

Have a question? Need help? CONTACT US!

These products may also be of interest to you

Optical Sorter for seed potatoes

Optical Sorter for potatoes

Optical Sorter for industry potatoes